Prodotti

- Apparecchiature di controllo di solidi

- Triple Deck Shale Shaker

- Moto lineare Shale Shaker

- Degasaggio sotto vuoto

- Pulitore di fanghi

- Dissabbiatore

- Desilter

- Decantazione centrifuga

- Sludge Vacuum Pump

- Verticale taglio asciuga

- Essiccazione Shale Shaker

- Getto fango Mixer

- Agitatore di fango

- Pompa centrifuga

- Shear pompa

- Pompa sommergibile liquami

- Pistola di fango

- Separatore Gas di fango

- Dispositivo di accensione del fuoco

- Pompa a vite

- Serbatoio di idratazione

- Serbatoio di fango

- Elevated Oil Tank

- Diesel Tank/Oil Tank

- Camera Motor Control Center

- Trasportatore a coclea

- Offshore Mud Skip Container

- Sistema di controllo di solidi

- Ricambi

- Drilling Rig

Contatto

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China  +86-29-89305761

+86-29-89305761 +86-29-89305769

+86-29-89305769

Casi

-

3000hp Drilling Rig Circulation System for 9000m U...

3000hp Drilling Rig Circulation System for 9000m Ultra Deep Drilling Proj...

-

2000hp Drilling Rig Mud Tank System for Saudi Arab...

2000hp Drilling Rig Mud Tank System for Saudi Arabia As earl...

Notizie di tecnologia

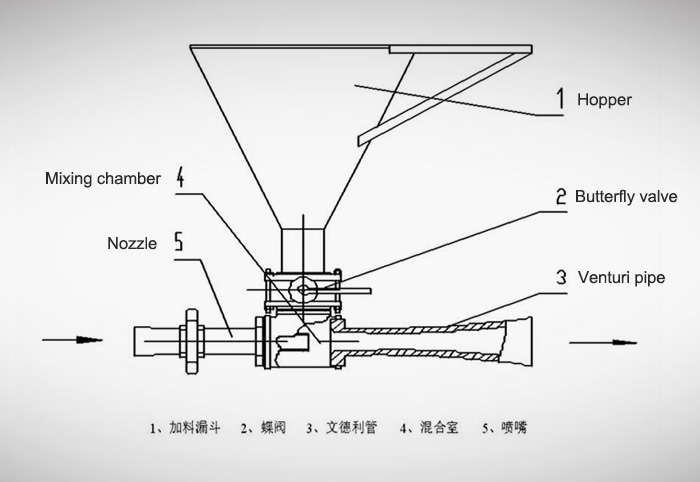

Working Principle of Drilling Mud Mixing Hoppers

2022-02-22

The drilling mud mixing hopper is a mud

mixing funnel designed using the Venturi principle. Also known as Venturi

drilling mud mixing hopper, its main components include nozzle, mixing chamber,

venturi tube, feeding hopper, butterfly valve, sand pump or shear pump.

Drilling mud mixing hopper is usually applied to oil drilling solids control,

trenchless and so on. Mainly used to configure drilling fluid, change drilling

fluid density, viscosity, water loss, etc. It is one of the special oilfield

equipment for weighting drilling fluid. The drilling mud mixing hopper is

equipped with sand pumps and pipelines to form a jet mixing device.

Working principle of drilling mud mixing hoppers

After the liquid is ejected from the

nozzle, it passes through the mixing chamber and enters the shearing tube. The

material is added to the mixing chamber from the funnel, and then enters the

shearing tube under the driving of the liquid flow from the nozzle, and is

dispersed and mixed in the process. The liquid flows out of the shear tube and

enters the circulation tank.

The shear tube is a hollow tube that gradually expands according to a certain curved surface. Its main function is to increase the shear force of the liquid in the tube, so that the material can be better dispersed and the pressure of the mixed liquid will enter the circulation tank.

The shear tube actually uses the Bernoulli effect of “fast flow, low pressure; slow flow, high pressure”. Because the liquid in the mixing chamber is sprayed from the nozzle at a high speed, the pressure is low at this time; after the liquid enters the shear tube, the cross section gradually becomes larger and the speed becomes smaller, so the pressure rises.

Installation of drilling mud mixing hoppers

After the mud is mixed, the pressure loss

is very large, so that the drilling fluid can be directly discharged into the

drilling fluid tank after being mixed by the drilling mud mixing hopper. The

funnel is usually installed on the top of the drilling fluid tank (that is,

installed at a high position), so that the mixed drilling fluid is directly

discharged into the drilling fluid tank without climbing.

After the drilling mud mixing hopper is installed at a high position, it is necessary to design a hoist or cantilever crane to lift the drilling fluid material to lift the drilling fluid material to the drilling fluid tank.

When the drilling mud mixing hopper is installed at a low position, a reasonable climbing angle should be designed, and the outlet should directly enter the drilling fluid tank to prevent the drilling fluid from overflowing from the funnel.

The drilling mud mixing hopper is usually directly driven by an electric mixing pump. When the mixing effect is not good, the distance between the drilling mud mixing hopper nozzle and the outlet end surface needs to be adjusted to achieve the best mixing effect.

Precedente :Four types of Sludge Dewatering Equipment